What We Offer

Replacement Spare Parts

IIM Encapsulation Equipment

IIM Encapsulation Equipment

IIM offers replacement spare parts and tooling for nutraceutical and pharmaceutical capsule filling and tablet compression machines. We perform machinery overhauls and upgrades, service and maintenance, and engineer and manufacture our own capsule filling equipment and size change kits. We also offer tablet compression parts including seals, cams, lubrication felts and wear parts in a variety of materials.

You can search by Manufacturer, OEM Part Number, IIM Part Number or Part Description.

IIM Encapsulation Equipment

IIM Encapsulation Equipment

IIM Encapsulation Equipment

IIM offers its very own line of capsule filling machinery all built and assembled in the USA!

Built for Nutra and Health Products with the accuracy and precision of Pharma standards.

Next Generation of

IIM Encapsulation Machines

IIM706 - High Speed / Low Volume

IIM1506 - High Speed / Mid Volume

IIM3006 - High Speed / High Volume

Lunch and Learn with IIM

IIM Encapsulation Equipment

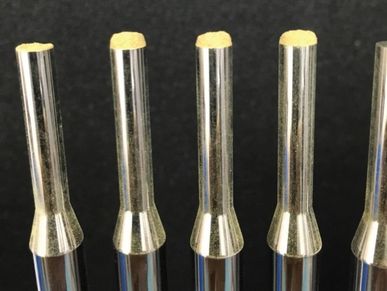

Companies frequently ask us how to improve the efficiency of their Bosch machines while running sticky powders. IIM's patent pending Blowout Blocks with Brushes have proven themselves time and time again to enhance your segment bore cleaning!

That’s just one of the many topics we cover during our popular and private Lunch & Learn sessions where mechanics, maintenance managers and their colleagues join us for a 60-minute interactive meeting to ask questions related to their industry and products.

Remote Service

Show us your encapsulation problem in real-time over video, or send us photos, and we will answer all of your questions and guide you on how to address the problem. Our hope is to save you a lot of money but steering you away from expensive OEM 'band-aids' or bad advice.

Complete Size Change Kits

Encapsulation Machine Upgrades

IIM offers high quality size change kits for all encapsulation machines.

Sizes 000, 00, 0, 1, 2, 3, 4, 5

Optional with all Elongated sizes

000/000e, 00/00e, 0/0e, 1/1e, 2/2e, 3, 4/4e

Encapsulation Machine Upgrades

Encapsulation Machine Upgrades

We offer custom design work for your encapsulation equipment. Custom hopper and auger designs to optimize your powder flow. Custom dosing disc to improve tamping results and minimize product loss and friction forces.

Any ideas that you or your Production Team has to improve your production efficiency, we can turn those ideas into reality!

Overhauls / Refurbishing

Overhauls / Refurbishing

Overhauls / Refurbishing

We offer complete machine overhauls and high quality refurbishing work. If you are seeing your production numbers fall, contact us to sign up for IIM's Machine Overhaul Program - we can bring your machine back to life!

In some special cases, customers have reported back to us that after a complete IIM Machine Overhaul, their machines were generating production numbers greater than when the machines were brand new

OEM Listings

Overhauls / Refurbishing

Overhauls / Refurbishing

Cutting-edge design software and state-of-the-art manufacturing equipment make it possible for our engineers to ensure complete design coverage down to the most intricate detail. From printed circuit boards and rubberized rollers to gearboxes and cogged belts, IIM has designed, cross-referenced, refurbished, repaired and manufactured thousands of items, made from a variety of materials including ferrous, non-ferrous, alloy, plastic, rubber and more!

Click below to search for your specific OEM.

Tamp Bulk Density Test

Overhauls / Refurbishing

Is your machine not hitting proper weights?

It is necessary to use a dosing disc with the correct thickness per your raw material's Tamp Bulk Density. To ensure you hit proper weights in your tamping ring and dosing station, we offer Tamp Bulk Density Testing in our NC facility and can recommend the proper dosing disc thickness to use with each product.

KKE Training and Calibration

KKE Training and Calibration

We fully support calibration, service, training and overhauls for your BOSCH KKE equipment.

KKE1500 KKE1700 KKE2000

KKE2500 KKE2600 KKE3800

Leave A Review

KKE Training and Calibration

Leave A Review

Please share your feedback of IIM's customer service, offerings, etc. Whether it was same day quoting, same day shipping, solving a machine issue, competitive pricing, high quality products, corrective action to an error or something else, we would love to hear about it. With your permission, we would like to share your feedback with our customers!

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.

Show Your Machines Some Love This Valentine’s Day!

Spare parts, preventative maintenance, and expert machine service—right when you need it. Contact IIM for all your capsule filling needs.